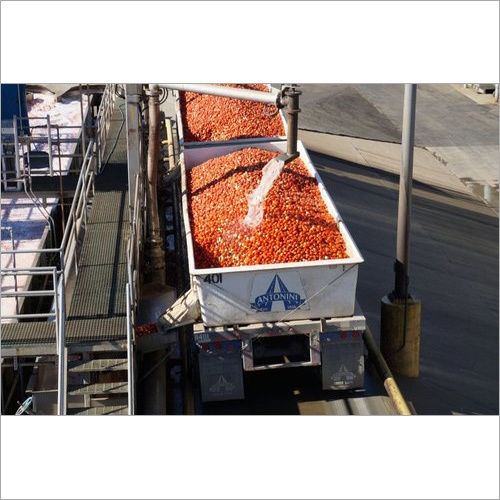

Tomato Processing Plant

Price 445200 INR/ Unit

Tomato Processing Plant Specification

- Frequency

- 50/60 Hz

- Noise Level

- Low

- Operating Temperature

- 60C to 95C

- Features

- High Efficiency, Easy Cleaning, Low Maintenance

- Machine Type

- Automatic Processing

- Heating Method

- Steam Based

- Power Source

- Electric

- Function Type

- Continuous

- Feeding System

- Automatic Feeder

- Phase

- Three Phase

- Automation Grade

- Fully Automatic

- Speed Mode

- Variable

- Product Type

- Tomato Processing Plant

- General Use

- Tomato Pulp and Paste Production

- Material

- Stainless Steel

- Type

- Industrial

- Capacity

- 2 to 20 Ton/hour

- Weight (kg)

- 12000

- Product Shape

- Rectangular

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Based

- Installation Type

- Complete Turnkey

- Voltage

- 380V / 440V

- Power

- 75 KW

- Dimension (L*W*H)

- 15000 mm x 6000 mm x 3200 mm

- Raw Material

- Fresh Tomatoes

- Feature

- Continuous Operation

- Color

- Silver

- Pump Type

- Centrifugal and Lobe Pumps

- Service Support

- On-Site Installation & Training

- Water Consumption

- Approx. 350 L/hr

- Suitable for

- Industrial Bulk Production

- Packaging Option

- Aseptic, Drum, Pouch

- Product Output

- Tomato Paste, Tomato Puree, Tomato Sauce

- Safety Features

- Emergency Stop, Overload Protection, Auto Shutdown

- Ambient Condition

- Humidity 85%

- Finish

- Food Grade Polished

- Processing Stages

- Washing, Sorting, Crushing, Pulping, Heating, Evaporation, Packing

- Cleaning System

- CIP (Clean-In-Place)

Tomato Processing Plant Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1 Week

About Tomato Processing Plant

We are manufacturer and supplier of high quality Tomato Processing Plant from Ghaziabad, India. We are manufacturing and supplying waste water treatment plant, water treatment plant, waste water recyclying plant and Industrial waste water treatment plant to various cities like, NEW DELHI, NOIDA, GHAZIABAD, MEERUT, SONIPAT, MANESAR, GREATER NOIDA, KANPUR, AMBALA, LUDHIANA, PAONTA SAHIB, MUZAFFARNAGAR, RANCHI,PATNA, JAIPUR, JAMMU, INDOR, GUJARAT, AHMEDABAD, MUMBAI, PUNE and many moreAdvanced Processing Stages for Superior Quality

The plant integrates washing, sorting, crushing, pulping, and evaporation to ensure pure, high-quality tomato products. Automated controls manage temperature and flow, guaranteeing consistency in every batch. Steam-based heating and CIP cleaning promote food safety and optimal hygiene for continual, large-scale operations.

Flexible Output and Packaging Solutions

Capable of producing tomato paste, puree, and sauce, our plant meets a range of industrial requirements. Choose from aseptic, drum, or pouch packaging to maintain product freshness and extend shelf life, all supported by a robust PLC-controlled system and versatile feeding mechanisms.

Engineered for Reliability and Safety

Built from food-grade stainless steel with a polished finish, the plant prioritizes operator safety with emergency stops, overload protections, and auto shutdown features. Low noise, efficient centrifugal and lobe pumps, and a computerized interface make it ideal for any modern bulk production facility.

FAQ's of Tomato Processing Plant:

Q: How does the tomato processing plant ensure hygienic operations?

A: The plant utilizes a Clean-In-Place (CIP) system, polished stainless steel surfaces, and advanced cleaning protocols. Automated washing and steam-based heating further promote sanitary processing, meeting strict food industry standards.Q: What are the main stages of the tomato processing workflow?

A: The plant's workflow includes washing, sorting, crushing, pulping, heating, evaporation, and final packing. Each stage is fully automated and designed for continuous operation, optimizing both efficiency and product quality.Q: When is service support available for installation and training?

A: On-site installation and training are offered upon plant delivery and commissioning. Our technical team in India will provide comprehensive support to ensure smooth setup and operator proficiency.Q: Where can the processed tomato products be packed?

A: Finished products can be packed as per your requirements: aseptic bags, drums, or pouches. The packaging systems are part of the integrated turnkey solution, maintaining product safety and shelf life.Q: What are the primary usage benefits of this plant for industrial producers?

A: The plant supports continuous, high-volume production with low maintenance, efficient raw material conversion, precise temperature control, and variable speed operation. These features maximize yield, reduce downtime, and deliver high-quality tomato products consistently.Q: How does the control system enhance production?

A: A PLC-based computer interface provides intuitive operation, real-time monitoring, and process adjustments. It ensures reliability, safety, and efficient energy use, all vital for large-scale, round-the-clock industrial production.Q: What is the plant's recommended operating environment?

A: The system is designed for ambient conditions with humidity up to 85%, operating reliably in various industrial settings across India. Stainless steel construction and robust protection features ensure durability and consistent output even in challenging environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tomato Processing Plant Category

Tomato Ketchup Plant

Price 445200 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Energy efficient, easy operation and cleaning

Operating Temperature : Up to 130C

Capacity : 5003000 kg/hr

Voltage : 380V

Sauce Making Machine

Price 445200 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Easy to Clean, Energy Saving, Hygienic Processing

Operating Temperature : 0120C

Capacity : 100 to 500 kg/hr

Voltage : 220240 V

Tomato Puree Processing Plant

Price 5000000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : High efficiency, Hygienic design, Userfriendly interface, Low power consumption

Operating Temperature : 50C to 105C

Capacity : 0.5 TPH to 5 TPH (Tons Per Hour)

Voltage : 380440 V

Tomato Pulp-Paste Making Machine

Price 48000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : High Yield, Low Maintenance, Ergonomic Structure

Operating Temperature : Ambient to 60C

Capacity : 300 Kg/hr

Voltage : 220 V

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free