Sauce Making Machine

Price 445200 INR/ Piece

Sauce Making Machine Specification

- Phase

- Single Phase or Three Phase

- Feeding System

- Continuous

- Noise Level

- Low

- Heating Method

- Electric/Steam

- Operating Temperature

- 0-120C

- Function Type

- Mixing, Grinding, Homogenizing

- Automation Grade

- Automatic

- Frequency

- 50/60 Hz

- Power Source

- Electric

- Features

- Easy to Clean, Energy Saving, Hygienic Processing

- Machine Type

- Semi-Automatic/Semi-Continuous

- Speed Mode

- Variable Speed

- Product Type

- Sauce Making Machine

- General Use

- Sauce, ketchup, puree preparation

- Material

- SS 304

- Type

- Food Processing Equipment

- Capacity

- 100 to 500 kg/hr

- Weight (kg)

- 300 kg

- Product Shape

- Rectangular

- Computerized

- No

- Automatic

- Yes

- Control System

- PLC Control

- Installation Type

- Floor Mounted

- Voltage

- 220-240 V

- Power

- 2.2 kW

- Dimension (L*W*H)

- 1600 x 800 x 1200 mm

- Raw Material

- Stainless Steel

- Feature

- Corrosion Resistant, High Efficiency

- Color

- Silver

- Safety Features

- Overload Protection, Emergency Stop Switch

- Cleaning System

- CIP (Clean-in-Place) compatible

- Output Product

- Tomato sauce, chili sauce, fruit puree, ketchup, paste

- Service Required

- Minimal - low maintenance design

- Motor Type

- Copper Winding Motor

- Surface Finish

- Mirror Polished

- Blade Material

- Stainless Steel

Sauce Making Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1 Week

About Sauce Making Machine

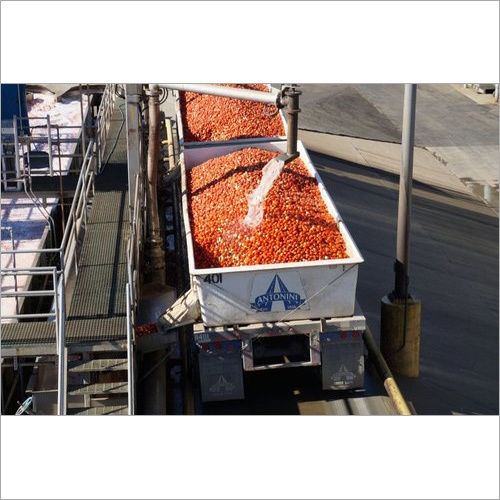

We have carved a niche in the market as a prime organization engaged in manufacturing and supplying Sauce Making Machines. These machines are used for making sauces from tomato and chili. Our diligent workforce uses quality grade stainless, procured from trusted vendors to manufacture these machines. Highly demanded in the market, these Sauce Making Machines come in different specifications for clients. We offer these machines at pocket friendly prices to clients.

Features:

- Easy to operate

- High operational fluency

- Robust construction

Efficient and Versatile Sauce Production

This machine is specifically designed to process a wide range of sauces and purees-including tomato, chili, fruit, and more-with consistent results. Its stainless steel blades and mirror-polished finish ensure high-quality, contaminant-free output, making it suitable for varied food applications.

State-of-the-Art Safety and Hygiene Features

Safety is prioritized through built-in overload protection and an emergency stop switch. The Clean-In-Place (CIP) system allows thorough, automated cleaning, maintaining hygiene and adhering to strict food safety standards without extensive manual intervention.

Ease of Operation and Low Maintenance

Automated controls via PLC system and a continuous feeding mechanism allow seamless operation. Its low-maintenance, minimal service requirements, and corrosion-resistant construction minimize downtime and enhance longevity, ensuring dependable productivity for food businesses.

FAQ's of Sauce Making Machine:

Q: How does the Sauce Making Machine operate and what products can it make?

A: The machine is automatic and PLC-controlled, handling the mixing, grinding, homogenizing, and heating of raw ingredients to produce tomato sauce, chili sauce, ketchup, fruit purees, and pastes. Its semi-automatic design enables high-capacity and continuous processing with minimal supervision.Q: What safety and hygiene features are included in the machine?

A: This equipment features overload protection, an emergency stop switch, and a CIP (Clean-In-Place) compatible cleaning system. These ensure operator safety and make regular sanitization efficient and consistent, maintaining high hygiene standards throughout operation.Q: What are the maintenance requirements for this machine?

A: Thanks to its low-maintenance design, service is required infrequently. Corrosion-resistant SS 304 construction and a mirror-polished surface reduce cleaning effort, while the CIP system further minimizes manual upkeep.Q: Where is this machine best installed, and what are its electrical specifications?

A: Optimally floor-mounted, the machine requires a power supply of 220-240 V with either single or three phase and operates at 50/60 Hz frequency. With a 2.2 kW power rating, it is compatible with most industrial settings in India.Q: What is the processing capacity and dimensional footprint of the equipment?

A: This sauce making equipment supports a capacity range of 100 to 500 kg/hr, making it suitable for small to medium scale production. Its dimensions are 1600 mm (L) x 800 mm (W) x 1200 mm (H), and it weighs approximately 300 kg.Q: How does the machine enhance efficiency and product quality?

A: Engineered for energy-saving and hygienic processing, the machine features a robust copper winding motor, variable speed modes, and stainless steel blades. These components work together to deliver smooth, homogenous sauces and pastes with low noise and high consistency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tomato Processing Plant Category

Tomato Ketchup Plant

Price 445200 INR / Piece

Minimum Order Quantity : 1 Piece

Weight (kg) : 3600 kg

Speed Mode : other, Variable frequency drive (VFD)

Features : Energy efficient, easy operation and cleaning

Power Source : Electric

Tomato Processing Plant

Price 445200 INR / Unit

Minimum Order Quantity : 1 Piece

Weight (kg) : 12000

Speed Mode : Variable

Features : High Efficiency, Easy Cleaning, Low Maintenance

Power Source : Electric

Tomato Puree Processing Plant

Price 5000000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight (kg) : 7000 12000 kg (varies with configuration)

Speed Mode : Variable

Features : High efficiency, Hygienic design, Userfriendly interface, Low power consumption

Power Source : Electric

Tomato Pulp-Paste Making Machine

Price 48000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight (kg) : 85 kg

Speed Mode : other, Single Speed

Features : High Yield, Low Maintenance, Ergonomic Structure

Power Source : Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free