VACUUM FILLING MACHINE

Price 75000 INR/ Piece

VACUUM FILLING MACHINE Specification

- Length

- 1000 mm

- Power Type

- Electric

- Color

- Silver

- Use Type

- Industrial

- Processing Type

- Automatic

- Product Capacity

- 10 to 60 bottles/min

- Machine Type

- Vacuum Filling Machine

- Running Speed

- Variable

- Feature

- High Vacuum Filling with Low Noise

- Voltage

- 220-240 V

- Production Output

- 500-3500 bottles/hour

- Width

- 800 mm

- Application

- Liquid Filling: Oils, Juices, Chemicals

- Phase

- Single/Three

- Height

- 1800 mm

- Weight

- 350 kg

- Filling Principle

- Gravity-Vacuum Based

- Bottle Size Compatibility

- 100ml to 1000ml

- Control System

- PLC Controlled

- Filling Range

- Adjustable

- Operating Temperature

- 5°C to 45°C

- Material

- SS304 Stainless Steel

- Safety Mechanism

- Emergency stop, Overload protection

- Design Standard

- Food grade hygienic design

- Cleaning Method

- Easy-to-dismantle parts for CIP

- No. of Filling Heads

- 2, 4, or 6

- Frequency

- 50/60 Hz

- Power Consumption

- 2.5 kW

- Filling Accuracy

- ±1%

- Conveyor Type

- SS Slat Conveyor

- Air Consumption

- 30-40 L/min

- Installation

- Floor Mounted

VACUUM FILLING MACHINE Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1 , , Piece Per Day

- Delivery Time

- 1 Week

About VACUUM FILLING MACHINE

We are manufacturer and supplier of high quality VACUUM FILLING MACHINE from Ghaziabad, India. We are manufacturing and supplying waste water treatment plant, water treatment plant, waste water recyclying plant and Industrial waste water treatment plant to various cities like, NEW DELHI, NOIDA, GHAZIABAD, MEERUT, SONIPAT, MANESAR, GREATER NOIDA, KANPUR, AMBALA, LUDHIANA, PAONTA SAHIB, MUZAFFARNAGAR, RANCHI,PATNA, JAIPUR, JAMMU, INDOR, GUJARAT, AHMEDABAD, MUMBAI, PUNE and many more

PS-VACUUM FILLING MACHINE (MODEL NO.PSV125): Four filling heads, suitable for filling all sizes and types of bottles to a predetermined level. Capacity20/30 bottles/minute. Suitable for filling all types of liquids to a predetermined level in glass, rigid HPDE & aluminum bottles with narrow necks. The machine is designed to accommodate ketchup, hot syrups & is fitted with over flow glass jars. Completely made of stainless steel 304. WITH COMPRESSOR.

Product Details

|

Grade |

SS 304 |

|

Capacity |

10 to 15 bottles/minute |

|

Power Consumption |

1HP |

|

Machine Type |

Automatic |

|

Material |

Stainless Steel |

|

Model |

PSV 126 |

Superior Filling Precision and Versatility

Built to deliver 1% filling accuracy and variable speed control, the Vacuum Filling Machine adapts to different bottle sizes (100ml to 1000ml) and product types. Its PLC-controlled interface ensures consistent, high-quality fills whether operating with 2, 4, or 6 filling heads. The adjustable filling range and gravity-vacuum principle make it a reliable choice for diverse industrial liquid applications.

Hygienic and Hassle-free Maintenance

Designed for food-grade industries, this machine uses corrosion-resistant SS304 stainless steel. Maintenance is simplified by its easy-to-dismantle components, enabling efficient Cleaning-in-Place (CIP) routines. Its robust construction supports CIP while ensuring cleanliness, safety, and ongoing compliance with hygienic standards required in food, beverage, and chemical sectors.

Safety and Energy Efficiency Built-In

Operators benefit from a range of integrated safety features, including emergency stop, overload protection, and air consumption controls (3040 L/min). With power consumption at just 2.5 kW and variable running speeds, the machine supports both single- and three-phase power supplies within 220240 V, making it energy-efficient and compatible with most industrial setups.

FAQs of VACUUM FILLING MACHINE:

Q: How does the vacuum filling machine ensure accurate and hygienic liquid filling?

A: The machine employs a gravity-vacuum filling principle alongside advanced PLC controls to maintain high accuracy (1%) and hygienic filling processes. Its SS304 stainless steel design, food-grade standards, and easy-to-dismantle parts enable thorough cleaning and CIP routines, making it safe for edible oils, juices, and chemicals.Q: What is the bottle size compatibility and how is the filling range adjusted?

A: It accommodates bottles ranging from 100ml to 1000ml. The filling range can be adjusted directly through its PLC interface, allowing users to tailor fill volumes according to product and packaging needs without manually changing machine configuration.Q: When is it necessary to use the emergency stop and overload protection features?

A: The emergency stop and overload protection mechanisms are employed during unexpected mechanical issues or if unsafe operating conditions are detected. These features safeguard both operators and machine components, ensuring operational safety and minimizing downtime.Q: Where can the vacuum filling machine be installed, and what are its space requirements?

A: The machine is floor-mounted and suitable for industrial environments, such as manufacturing plants and food processing units. Its compact dimensions1000 mm in length, 1800 mm in height, and 800 mm in widthfacilitate easy integration into existing production lines.Q: What is the cleaning process for this vacuum filling machine?

A: The cleaning process is streamlined due to easy-to-dismantle parts, enabling efficient Cleaning-in-Place (CIP). Operators can quickly disassemble components for thorough sanitation, helping maintain food grade hygiene and reducing machine downtime between product changeovers.Q: How does the machine benefit industrial production operations?

A: With automatic processing, high product capacity (1060 bottles per minute), and versatile output (5003500 bottles per hour), the machine enhances operational efficiency, ensures consistent product quality, and supports large-scale production while maintaining food safety and energy efficiency.Q: Can this machine be used for different types of liquids, and who are its typical users?

A: Yes, the machine is suitable for a variety of liquid products, including edible oils, juices, and chemicals. Its typical users are manufacturers, exporters, and suppliers in the food, beverage, and chemical sectors who require reliable, hygienic, and high-speed filling solutions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sauces Jam Processing Plant Category

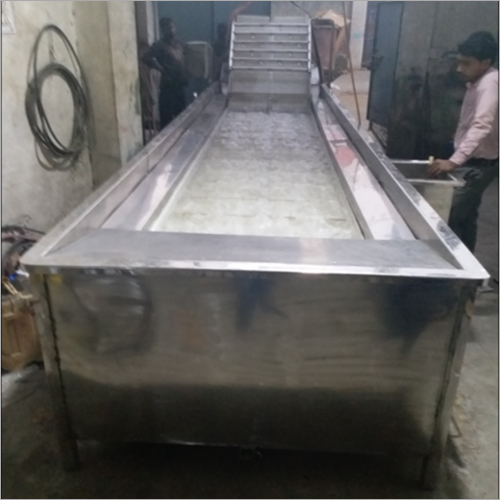

Fruit Washing Machine

Price 540000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Product Capacity : 500 kg per hour

Machine Type : Other, Fruit Washing Machine

Power Type : Electric

Length : 2800 mm

FRUIT WASHING MACHINE

Price 396000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Capacity : 8001000 kg/h

Machine Type : Other, Fruit Washing Machine

Power Type : Electric

Length : 2500 mm

Colloidal Mill

Price 108000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Capacity : 51000 LPH

Machine Type : Other, Colloidal Mill

Power Type : Electric

Length : 600 mm

Twin Pulper

Price 306000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Product Capacity : 1.5 Ton/Hr

Machine Type : Other, Twin Pulper

Power Type : Electric

Length : 1200 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free