Colloidal Mill

Price 108000 INR/ Piece

MOQ : 1 Piece

Colloidal Mill Specification

- Power Type

- Electric

- Use Type

- Industrial

- Phase

- Single/Three Phase

- Width

- 350 mm

- Running Speed

- 2800 RPM

- Processing Type

- Batch & Continuous

- Height

- 1000 mm

- Product Capacity

- 5-1000 LPH

- Voltage

- 220-240 V

- Production Output

- Up to 1000 LPH

- Feature

- High Shear Performance, Corrosion Resistant

- Machine Type

- Colloidal Mill

- Application

- Food, Pharmaceutical, Chemical, Cosmetic, Paint, Dye industries

- Length

- 600 mm

- Color

- Stainless Steel

- Weight

- 80 kg (approx)

- Material of Construction

- Stainless Steel 304/316

- Feed Hopper Capacity

- Approx 15 Litres

- Rotor-Stator Gap Adjustment

- Manual

- Surface Finish

- Mirror/Matte

- Mount Type

- Floor Mounted

- Adjustable Gap

- Yes (for fine or coarse grinding)

- Min. Particle Size

- Up to 5 Microns

- Safety Features

- Overload Protection

- Noise Level

- Low

- Cooling System

- Water Jacketed (optional)

- Discharge Outlet Size

- 1 inch

- Motor Power

- 2 HP - 5 HP

Colloidal Mill Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 3 Pieces Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Colloidal Mill

PS COLLOIDAL MILL (MODEL NO. PSCM134): Suitable for fine grinding and homogenizing of liquids and pastes like juices, squash and ketchup etc. contact parts in SS304, capacity 250 kgs/hrs. fitted with 3 HP, 3 ph.

Superior Grinding and Particle Size Control

Engineered with a manually adjustable gap between the rotor and stator, this colloidal mill allows precision control for fine or coarse grinding, achieving particle sizes as small as 5 microns. Whether your process requires uniform emulsification or robust dispersion, the machine delivers consistency batch after batch.

Durable Construction and Flexible Operation

Crafted from premium stainless steel (304/316), the mill resists corrosion and withstands rigorous industrial use. It is floor-mounted and supports both batch and continuous processing modes, making it suitable for versatile production requirements in food, pharmaceutical, and chemical plants.

User-Friendly, Safe, and Low Maintenance

Benefit from advanced safety with overload protection, low noise levels during operation, and a sleek mirror or matte surface finish. The optional water-jacketed cooling ensures optimal temperature control, maintaining product quality and prolonging machine life. Routine cleaning and gap adjustments are straightforward, boosting operational uptime.

FAQs of Colloidal Mill:

Q: How do you adjust the grinding fineness in the colloidal mill?

A: The grinding fineness is easily adjusted using the manual rotor-stator gap adjustment feature. By narrowing or widening the gap, operators can achieve either fine or coarse grinding, tailoring particle size down to as small as 5 microns according to the applications requirements.Q: What materials can be processed with this colloidal mill?

A: This mill is designed for processing a wide range of materials, including food products, pharmaceuticals, chemicals, cosmetics, paints, and dyes. Its corrosion-resistant stainless steel construction makes it suitable for handling even aggressive or sensitive ingredients safely.Q: When is a water-jacketed cooling system recommended for the colloidal mill?

A: The optional water-jacketed cooling system is advisable when processing heat-sensitive materials or running prolonged batches. It maintains a consistent product temperature, which preserves material integrity and prevents thermal degradation during high-shear grinding.Q: Where is the colloidal mill typically installed in an industrial setup?

A: The machine is floor-mounted for stability and is best placed in processing areas with accessible power supply (220240 V, single or three phase) and provision for feed and discharge. Its compact footprint (600 x 350 x 1000 mm) fits well into food manufacturing, pharmaceutical, chemical processing, or cosmetic production environments.Q: What safety features are incorporated in this machine?

A: The colloidal mill includes built-in overload protection to safeguard both operators and the motor. Additionally, its low noise operation and sturdy stainless steel body help minimize workplace risks and ensure compliance with industrial safety standards.Q: How does using this colloidal mill benefit industrial production?

A: Utilizing this colloidal mill enhances production efficiency by delivering high throughput (up to 1000 LPH) and consistent product quality. Its adjustable gap system, robust stainless steel body, and efficient electric motor ensure reliable performance while reducing maintenance and downtime.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sauces Jam Processing Plant Category

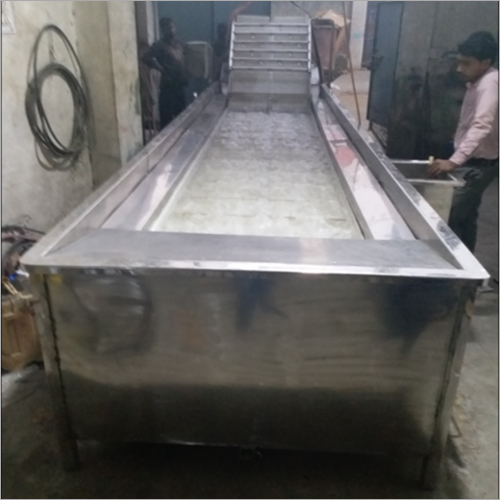

FRUIT WASHING MACHINE

Price 396000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 380V

Production Output : Continuous

Height : 1300 mm

Processing Type : Automatic

Fruit Washing Machine

Price 540000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Voltage : 380 V

Production Output : Continuous

Height : 1200 mm

Processing Type : Automatic

BUCKET ELEVATOR

Price 252000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Voltage : 415 V

Production Output : Variable

Height : 4500 mm

Processing Type : Automatic

Pulprizer .

Minimum Order Quantity : 1 Set

Voltage : 415 Volt (v)

Production Output : 60 Kg/Hr

Height : 60 Inch

Processing Type : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free