Pulprizer .

Pulprizer . Specification

- Application

- Pulping Fruits And Vegetables

- Running Speed

- 1440 RPM

- Weight

- 260 Kilograms (kg)

- Length

- 38 Inch

- Width

- 22 Inch

- Power Type

- Electric

- Production Output

- 60 Kg/Hr

- Machine Type

- Pulprizer

- Height

- 60 Inch

- Color

- Blue

- Use Type

- Industrial

- Origin

- India

- Phase

- Three Phase

- Processing Type

- Automatic

- Voltage

- 415 Volt (v)

Pulprizer . Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 1 Set Per Week

- Delivery Time

- 15 Days

- Main Domestic Market

- All India

About Pulprizer .

We are manufacturer and supplier of high quality Pulprizer from Ghaziabad, India. We are manufacturing and supplying waste water treatment plant, water treatment plant, waste water recyclying plant and Industrial waste water treatment plant to various cities like, NEW DELHI, NOIDA, GHAZIABAD, MEERUT, SONIPAT, MANESAR, GREATER NOIDA, KANPUR, AMBALA, LUDHIANA, PAONTA SAHIB, MUZAFFARNAGAR, RANCHI,PATNA, JAIPUR, JAMMU, INDOR, GUJARAT, AHMEDABAD, MUMBAI, PUNE and many more

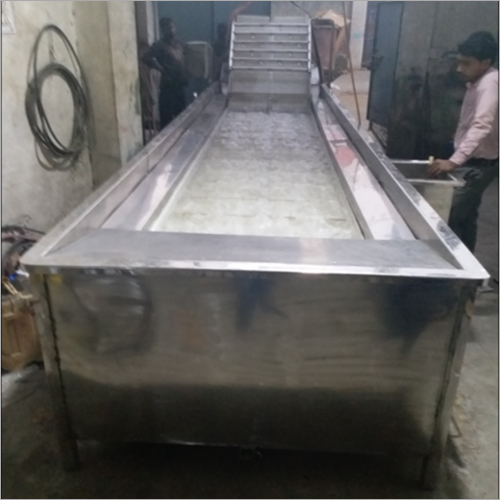

Pulprizers are specially designed to make paste/pulp of vegetables and fruits like Chilli, Ginger, Garlic, Onion, Carrot etc. The unit is mounted on M.S. Frame and covered with S.S. Sheets. All the contact parts are made of SS-304.

Product Details

| Leg Material | Mild Steel |

| Capacity | 1 Ton/Hr |

| Automation Grade | Automatic |

| No Of Leg | 4 |

| Material | Stainless Steel |

| Material Grade | SS 304 |

Automated Pulping Excellence

The Pulprizer utilizes advanced automatic processing technology to maximize efficiency in industrial environments. Its high-speed motor and continuous feed system ensure consistent and uniform pulping of various fruits and vegetables. The machines sturdy construction and impressive output capacity streamline production, enabling food processors to meet large-scale demand safely and efficiently.

Robust Design and Engineering

Crafted in India, the Pulprizer boasts a blue-hued, corrosion-resistant body. Designed for heavy industrial use, the machine maintains stability during operation thanks to its optimal weight distribution and dimensions, allowing reliable use in diverse factory settings. Its three-phase electrical setup and 415-volt power requirements make it a trustworthy choice for demanding applications.

FAQs of Pulprizer .:

Q: How does the Pulprizer facilitate fruit and vegetable pulping in an industrial environment?

A: The Pulprizer is designed for automatic, high-volume pulping of a wide range of fruits and vegetables. Its continuous feed and high-speed operation allow it to efficiently convert raw produce into pulp, streamlining food processing workflows.Q: What types of production facilities are best suited for using the Pulprizer?

A: The Pulprizer is ideal for industrial food processing units, especially those focusing on fruit and vegetable-based products such as juices, purees, and concentrates. Its robust design and automatic processing capabilities cater to manufacturers, exporters, and suppliers who require consistent, high-throughput pulping.Q: When should I consider installing a Pulprizer in my processing plant?

A: If your production demands exceed manual or semi-automatic pulping capacities, or if you require reliable, continuous operation at high volumes, integrating the Pulprizer will significantly boost your efficiency and reduce labor costs.Q: Where is the Pulprizer exported and manufactured?

A: The Pulprizer is manufactured and exported from India, serving clients worldwide who seek dependable machinery for the pulping of fruits and vegetables in their industrial operations.Q: What is the process for operating the Pulprizer?

A: Operation is straightforward: connect to a three-phase, 415-volt power supply, load the machine with cleaned fruits or vegetables, and initiate the automatic pulping cycle. The machines user-friendly interface ensures consistent performance at a running speed of 1440 RPM.Q: How can using the Pulprizer benefit my industrial production line?

A: Utilizing the Pulprizer can enhance productivity, ensure uniform pulp quality, and reduce manual labor, leading to cost savings and improved operational efficiency for food processing businesses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sauces Jam Processing Plant Category

FRUIT WASHING MACHINE

Price 396000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 380V

Processing Type : Automatic

Phase : Three Phase

Feature : Energy Efficient, Low Noise, High Cleaning Efficiency

Fruit Washing Machine

Price 540000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Voltage : 380 V

Processing Type : Automatic

Phase : Three Phase

Feature : High Efficiency, Easy Operation

VACUUM FILLING MACHINE

Price 75000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Voltage : 220240 V

Processing Type : Automatic

Phase : Single/Three

Feature : High Vacuum Filling with Low Noise

BUCKET ELEVATOR

Price 252000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Voltage : 415 V

Processing Type : Automatic

Phase : Three Phase

Feature : Durable, Low Maintenance, High Efficiency

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free