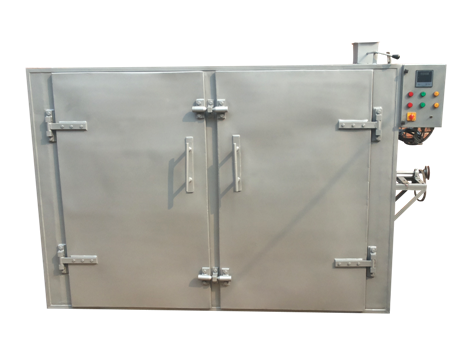

Tray Drayer

Price 72900 INR/ Piece

Tray Drayer Specification

- Heat Source

- Electric / Steam

- Power Consumption

- Approx. 3-15 units/hr

- Fuel Type

- Electricity / Steam

- Power

- 3 kW 15 kW (Model dependent)

- Temperature

- 50C - 150C adjustable

- Material

- Stainless Steel (304/316)

- Voltage

- 220V / 380V

- Technology

- Hot Air Circulation

- Dimension (L*W*H)

- Customizable Standard: 1000mm x 800mm x 1800mm

- Safety Features

- Overheat protection, Emergency cut-off

- Temperature Control

- Digital PID controller

- Control Panel

- Microprocessor based

- Door Type

- Gasketed, front-loading

- Installation Type

- Floor standing

- Finish

- Matte / Mirror finish

- Tray Material

- Stainless Steel

- Number of Trays

- 12, 24, 48 or custom

- Loading Capacity

- 20 kg to 100 kg

- Air Circulation

- Uniform through powerful blower

- Application

- Drying food, chemicals, pharmaceuticals, herbs

- Insulation

- Double wall with mineral wool

Tray Drayer Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1 , , Piece Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Tray Drayer

PS-TRY DRAYER: Electrically operated, Digital Temperature controller cum Indicator is used for controlling temperature, double walled inner and outer body made of Mild Steel beautifully painted, glass wool insulation, temperature range 500C to 2500 C Temperature with an accuracy of 10C, To work on 220Volts AC main.

Product Details

Available In | 12, 24, 48 and 96 trays, 192 trays |

Capacity | 20- 1000 kg/batch |

Max Temperature | 250 degree celcious |

Automatic Grade | Semi-Automatic |

Surface Finish | Polished |

Temperature Control | Upto 100 degree |

Efficient Drying with Maximum Safety

Utilizing advanced hot air circulation technology and mineral wool insulation, the Tray Dryer delivers consistent drying performance while minimizing energy loss. Its overheat protection system and emergency cut-off ensure safe, uninterrupted operation.

Flexible Design for Diverse Applications

With options for 12, 24, 48, or custom trays made from high-grade stainless steel (304/316), you can select the configuration that matches your workload. The dryer accommodates a wide range of materialsfrom herbs to pharmaceuticalsand is available with customizable dimensions to fit your space.

Smart Control and User-Friendly Operation

Featuring a microprocessor-based control panel and digital PID temperature controller, the Tray Dryer enables straightforward operation and precise process control. Its matte or mirror finish offers easy cleaning and maintenance, while the front-loading gasketed door supports effortless access during loading and unloading.

FAQs of Tray Drayer:

Q: How does the Tray Dryer achieve uniform drying of materials?

A: The Tray Dryer uses hot air circulation technology, where powerful blowers distribute air evenly throughout the chamber. This ensures every tray receives consistent heat, resulting in uniform drying of contents such as food, chemicals, pharmaceuticals, and herbs.Q: What materials and finishes are available for the trays and dryer body?

A: Trays are made from high-quality stainless steel (304/316) for durability and hygiene. The dryer body is also constructed from stainless steel and is available in either a matte or mirror finish, both offering excellent resistance to corrosion and ease of cleaning.Q: When should I choose a custom tray or capacity configuration?

A: Custom tray or capacity options are recommended when your production requirements exceed standard sizes or when you need specific dimensions to fit unique process needs. This flexibility allows you to optimize the dryer for your operational demands.Q: Where can the Tray Dryer be installed, and what setup is required?

A: The unit is designed for floor-standing installation and can be set up in industrial plants, laboratories, or commercial kitchens. It requires an electrical or steam connection (220V/380V, 3 kW-15 kW), and installation involves positioning the dryer, connecting the utilities, and configuring the control panel.Q: How does the PID temperature controller improve the drying process?

A: The digital PID controller provides accurate and stable temperature management within the adjustable range of 50C to 150C. This precision reduces product degradation, helps achieve optimal drying times, and maintains consistent quality across batches.Q: What safety features does the Tray Dryer include for user protection?

A: Integrated safety features such as overheat protection and emergency cut-off mechanisms safeguard operators and prevent damage to materials during the drying process, ensuring reliable operation and minimizing risks.Q: What are the operational benefits of using a Tray Dryer for drying applications?

A: The Tray Dryer offers rapid, energy-efficient drying, flexible configuration, robust safety systems, and ease of use. Its ability to handle diverse materials and customizable features help improve productivity and maintain high-quality results in industrial drying operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Dryers Category

Tray Dryer Machine

Price 153000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Heat Source : Electric or Steam

Technology : Forced Circulation

Voltage : 220240V AC

Power Consumption : 3 kW per hour

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS